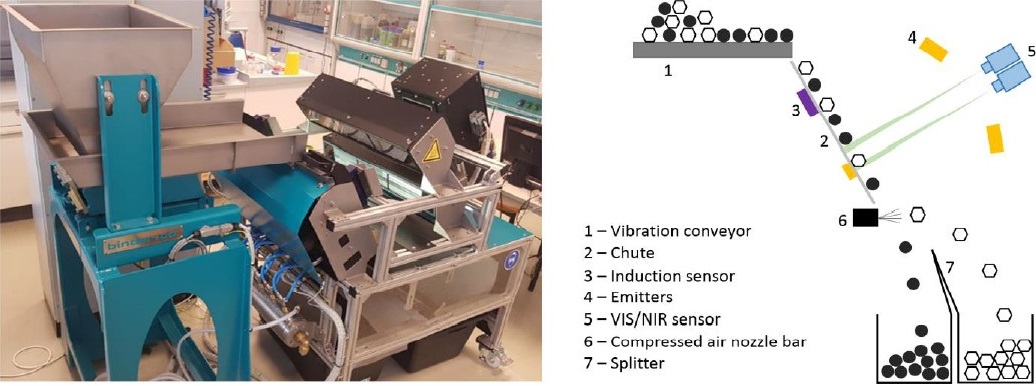

Experimental sensor-based sorting setup

Sensor-based sorting is used in waste management for sorting and analyzing waste streams and bulk materials. It is a non-contact process that offers a great deal of flexibility to cope with a wide variety of tasks.

The Chair for Waste Processing Technology and Waste Management (AVAW) has an experimental sensor-based sorting setup for university and industrial research projects designed as a two-way machine. A grain size range from 5 to 300 mm can be processed. The feed takes place via a vibrating conveyor (1) followed by a glass chute (2) (see the followed figure).

The experimental sensor-based sorting setup contains three sensors that can be used for different waste streams:

- Near-infrared sensor (NIR) (5): waste glass, paper and cardboard, plastics, electronic scrap as well as construction and demolition waste

- High-resolution line scan camera (VIS) (5): plastics, wood, paper and cardboard, waste glass as well as construction and demolition waste

- Induction sensor (3): electric conductors.

It is also possible to combine several sensors to solve very complex tasks. One example is combining a VIS and NIR sensor for sorting clear PET bottles out of a lightweight packaging fraction.

Functional schematic of the experimental sensor-based sorting setup at AVAW

Application example for VIS technology

The feed material is mixed stained glass shards in a typical grain size range of 2 - 24 mm. A high-resolution line scan camera (VIS) is used as the sensor. The aim is the purest possible extraction of broken green glass from the feed material.

The material is separated using a vibration conveyor (1) and then moved into the sensor's exposure area via a slide or chute (2).

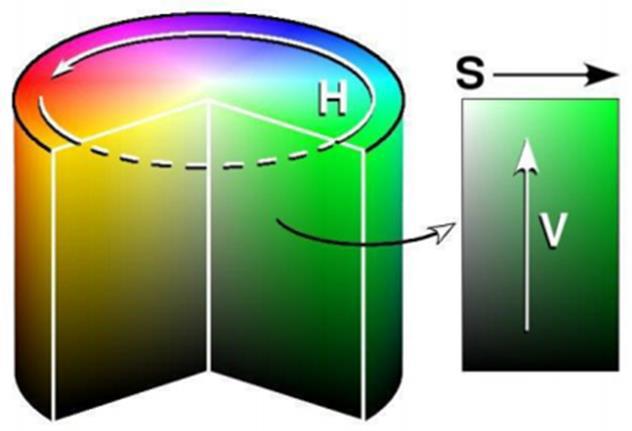

This sensor (5) consists of an emitter (4) and a detector (5). In this case, halogen lamps, fluorescent tubes, or LED strips are usually chosen as emitters. The emitter's radiation is partially reflected by the individual pieces of glass and measured by the detector. The detector is connected to a computer that records the detected color in the "color cylinder" with the help of software. In terms of the color sector (Hue, H), the brightness level (Value, V) and the saturation circle (Saturation, S) in a previously created color cylinder model (see the followed figure) are compared and thereby assigned to a defined group. For example, in this task, the groups are green, brown, or white glass.

Color cylinder for creating the VIS sorting model according to the color sector (Hue, H), the brightness level (Value, V) and the saturation circle (Saturation, S)

If a piece of glass, which belongs to the "green glass" group, is recognized, it must be separated from the remaining fragments according to the task. That is done using a compressed air blast. A valve strip (6) downstream of the sensor opens one or more valves when the broken glass is in front of the valve strip. The green shard of glass is "shot out" over the separating edge (7). All different colored broken glass are deliberately not "shot out".

Application example for NIR technology

The feed material is a mixed light packaging fraction after previous passage through a drum sieve with a sieve grain diameter of 80 mm, which has a typical grain size range of 80 - 300 mm (height of a PET bottle). Near-infrared spectroscopy (NIR spectroscopy) is used as sorting technology. The aim is to achieve the purest possible output of PET.

The material is separated using a vibration conveyor (1) and then moved into the sensor's exposure area via a slide or chute (2).

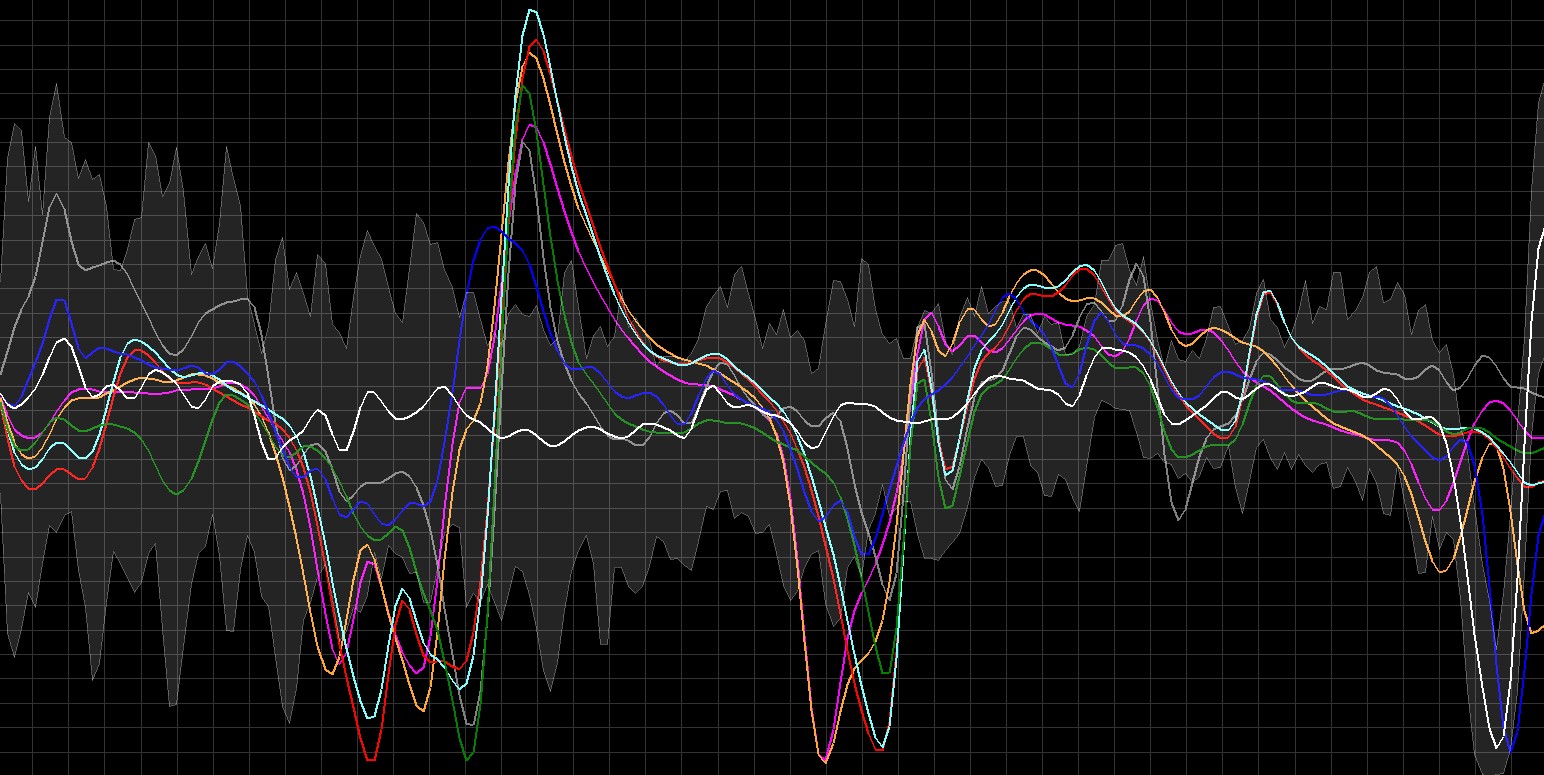

Modern near-infrared (NIR) sensors (5) cover a wavelength range from around 1000 to 2500 nm. Halogen lamps, for example, can be used as emitters (4). In the visible light (VIS) range, the radiation is selectively reflected by the objects examined and then measured by a detector (5). This spectrum contains information that allows conclusions about the chemical composition of the investigated objects.

This technology makes it possible, for example, to recognize different types of plastic based on specific molecule groups - in the application example PET (see followed figure). These waves are excited to vibrate by the incident radiation. The wave oscillation energy is split in the reflected and transmitted radiation so that a corresponding absorption band results in the resulting spectrum. The detected spectrum is converted into an electrical signal and processed in an associated evaluation unit. The measured spectrum is compared with several reference spectra from a database. If the spectrum matches one of these spectra, the particle is recognized as the related material and can be sorted. The detection of dark (soot-blackened) materials is a limiting factor that plays a role in plastics processing in particular. These particles usually do not reflect a spectrum detected by the NIR sensor of a sensor-based sorting machine. (Gundupalli et al., 2017; Hendrik Beel, 2017)

Recorded spectra using NIR technology on the experimental sensor-based sorting setup: For example, the white area provides the deviation of the spectra for PET per wavelength for the entire wavelength range, while the white line provides the mean value spectrum of PET for each wavelength over the NIR spectral range

Recorded spectra using NIR technology on the experimental sensor-based sorting setup: For example, the white area provides the deviation of the spectra for PET per wavelength for the entire wavelength range, while the white line provides the mean value spectrum of PET for each wavelength over the NIR spectral range

If packaging from the "PET" group is recognized, it must be separated from the rest of the lightweight packaging fraction according to the task. That is done using a compressed air blast. A valve bar (6) downstream of the sensor opens one or more valves when the PET packaging is in front of the valve bar. The PET packaging is "shot out" over the separating edge (7). All other types of plastic are deliberately not "shot out".

Tasks and applications that have been worked on in research projects on the experimental sensor-based sorting setup

- Sample characterization and determination of the composition,

- Creation of a digital grain size distribution,

- Discharge of contaminants,

- Enrichment of valuable substances,

- Sorting of bulk goods according to substance groups and

- Validation of sorting/separation results.

Followed waste streams have already been processed in research projects or preliminary trials on the experimental sensor-based sorting setup

- Commercial waste (NIR technology)

- 04/2017 - 04/2021 ReWaste 4.0 (K-Project)

- Landfill material (NIR technology)

- 08/2015 - 08/2019 NEW-MINE (H2020, MSCA)

- Products (NIR technology)

- 04/2018 - 01/2019 NewFridgeRec (Industrial contract research, shredded fridges)

- 04/2018 - 09/2018 SheathBlend (Industrial contract research, cable sheaths)

- 10/2015 - 04/2019 BAT-SAFE (FFG, Bridge, batteries)

- Construction and demolition waste (C&D waste) (VIS & NIR technology)

- 08/2018 - 08/2021 RecyMin (FFG, Bridge)

- 12/2018 - 01/2019 C&D light fraction waste (Preliminary tests)

- 10/2018 - 01/2019 FBS (Industrial contract research)

- 04/2018 - 01/2019 BrickSort (Industrial contract research)

- 05/2019 Wärmedämmverbundsystem (Preliminary tests)

- Polymers and plastic waste (VIS & NIR technology)

- 01/2021 - 12/2024 PCCL-K1, Phase 2 (COMET-Centre)

- 02/2021 - 01/2022 Multilayer Detection (Future Fund Styria)

- 08/2020 - 07/2023 C-Planet (H2020, MSCA)

- 01/2020 - 12/2022 EsKorte (FFG, Production of the Future)

- 01/2017 - 12/2020 PCCL-K1, Phase 1 (COMET- Centre)

- 03/2020 - 07/2020 NIRloss (Industrial contract research)

- 03/2020 - 05/2020 ColSort (Industrial contract research)

- 01/2019 - 09/2019 Waste Guide (Industrial contract research)

- 06/2019 - 09/2019 FlakePotential (Industrial contract research)

- Compost (VIS & NIR technology)

- 09/2018 - 02/2021 DeSort (FFG, Bridge)

- Refuse-derived fuel (RDF) (NIR technology)

- 11/2020 - 10/2021 Throughput Rate (Innovation cheque with retention)

- 04/2018 - 01/2019 POrecover (Industrial contract research)

- Cullets & metals (VIS & NIR technology)

- 06/2020 Non-ferrous metal residues out of cullet processing (Preliminary tests)

Publications and theses

Peer-reviewed paper, published by 01st April 2021

- Weissenbach, T., Sarc, R. (2021): Investigation of particle-specific characteristics of non-hazardous, fine shredded mixed waste. Waste Management. 119 (2021) 162–171. https://doi.org/10.1016/j.wasman.2020.09.033.

- Weissenbach, T., Sarc, R. (2021) Investigation of particle-specific characteristics of non-hazardous, fine shredded mixed waste. Waste Management Journal 2013/2020. In Review-Prozess.

- Küppers, B.; Schlögl, S.; Friedrich, K.; Lederle, L.; Pichler, C.; Freil, J.; Pomberger, R.; Vollprecht, D. (2020): Influence of material alterations machine impairment on throughput related sensor-based sorting performance. Waste Management & Research, DOI 10.1177/0734242X20936745.

- Hernández Parrodi, J.C., Vollprecht, D.; Pomberger, R. (2020): Case Study on Enhanced Landfill Mining at Mont-Saint-Guibert Landfill in Belgium: Physico-Chemical Characterization and Valorization of Combustibles and Inert Fractions. Detritus, DOI 10.31025/2611-4135/2020.13941.

- Küppers, B.; Seidler, I.; Koinig, G.R.; Pomberger, R.; Vollprecht, D. (2020): Influence of Throughput Rate and Input Composition on Sensor-Based Sorting Efficiency. Detritus 9, 59-67. DOI 10.31025/2611-4135/2020.13906.

- Möllnitz, S.; Khodier, K.; Pomberger, R.; Sarc, R. (2019): Grain size dependent distribution of plastic types in coarse-shredded commercial and municipal waste. Waste Management 103, 388-398. DOI: 10.1016/j.wasman.2019.12.037.

- Hernández Parrodi, J.C., Raulf, K., Vollprecht, D., Pretz, T., Pomberger, R. (2019): Case Study on Enhanced Landfill Mining at Mont-Saint-Guibert Landfill in Belgium: Mechanical Processing of Fine Fractions for Material and Energy Recovery. Detritus 8, 62-78. DOI 10.31025/2611-4135/2019.13878.

- Garcia Lopez C.; Ni, A.; Hernández Parrodi, J.C.; Küppers, B.; Raulf, K.; Pretz, T. (2019): Characterization of landfill mining material after ballistic separation to evaluate material and energy recovery potential. Detritus 8, 5-23. DOI 10.31025/2611-4135/2019.13780.

- Küppers, B.; Chen, X.; Seidler, I.; Friedrich, K.; Raulf, K.; Pretz, T.; Feil, A.; Pomberger, R.; Vollprecht, D. (2019): Influences and Consequences of Mechanical Delabelling on PET Recycling. Detritus 6, 39-48. DOI 10.31025/2611-4135/2019.13816.

- Küppers, B.; Schlögl, S.; Oreski, G.; Pomberger, R.; Vollprecht, D. (2019): Influence of surface roughness and surface moisture of plastics on sensor-based sorting in the near infrared range. Waste Management and Research 37(8), 843-850. DOI: 10.1177/0734242X19855433.

Further contributions and proceedings, published by 01st April 2021

- Weissenbach, T., Sarc, R. (2020): Erstellung einer Datenbank zur Echtzeitanalytik von Abfällen (Development of a database for real-time analysis of waste). Oral presentation & written contribution. In: Pomberger et al. [Ed]: Recy & DepoTech 2020: Konferenzband zur 15. Recy & DepoTech Band. AVAW Eigenverlag, Band 15. S. 153-158.

- Friedrich, K. (2019): Sensorgestützte Sortierung von Leichtgut aus der Schwimm-Sink-Trennung einer Baurestmassenfraktion mittels Nahinfrarotspektroskopie (Sensor-based sorting of a construction and demolition waste light fraction from swin-sink separation using near-infrared spectroscopy). 9. Wissenschaftskongress „Abfall- und Ressourcenwirtschaft“. DGAW. Amberg-Weiden.

- Möllnitz, S.; Khodier, K.; Pomberger, R.; Sarc, R. (2019): Grain size dependent distribution of plastic types in coarse-shredded commercial and municipal waste. Conference Proceedings. Sardinia Symposium 2019. Cagliari.

- Küppers, B.; Vollprecht, D.; Pomberger, R. (2019): Einsatz sensorgestützter Sortierverfahren im Landfill Mining (Application of sensor-based sorting technologies in landfill mining). Mineralische Nebenprodukte und Abfälle 6, 600-616.

- Kunststoffe im gemischten Gewerbeabfall - In welcher Form und Wo? (Polymers in mixed commercial waste - How do they look like and where can they be found?). Österreichische Abfallwirtschaftstagung 2019 „Vom Wert- zum Werkstoff. Die Umsetzung des EU-Kreislaufwirtschaftspakets in Österreich“. ÖWAV. Eisenstadt.

- Küppers, B.; Möllnitz, S. (2018): Versuchstand für sensorgestützte Erkennung und Sortierung (Experimental setup for sensor-based identification and sorting). Konferenzbeitrag und Posterbeitrag. 8. Wissenschaftskongress „Abfall- und Ressourcenwirtschaft“. DGAW. Wien.

- Küppers, B.; Vollprecht, D.; Pomberger, R. (2018): Einfluss von Verschmutzungen auf die sensorgestützte Sortierung (Influence of impurities on sensor-based sorting). Recy&DepoTech 14(1), 111-118.

- Vollprecht, D.; Küppers, B.; Pomberger, R.; Machiels, L.; Bernardo, E.; Krook, J. (2018): Das "EU Training Network for Resource Recovery Through Enhanced Landfill Mining" (NEW-MINE). Recy&DepoTech 14(1), 561-568.

- Möllnitz, S.; Sarc, R.; Eichner, J. (2018): Vergleich zweier Methoden zur Abschätzung des Materialgehaltes in ausgewählten Abfallballen (Comparison of two methods for estimating the material content in selected waste bales). Recy&DepoTech 14(1), 767-772.

- Vollprecht, D. (2018): Neue Technologien für alten Abfall (New technologies for old wastes). Umweltjournal 2018(6), 9.

- Küppers, B.; Pomberger, R. (2017): Entwicklungen in der sensorgestützten Sortiertechnik (Developments in sensor-based sorting technologies). Österreichische Abfallwirtschaftstagung 2017 „Die Digitalisierung der Abfallwirtschaft“. ÖWAV. Graz.

Doctoral theses, completed by 01st April 2021

- Potential of Sensor-Based Sorting in Enhanced Landfill Mining under Consideration of the Effects of Defilements (Bastian Küppers, 2020)

- Production of Refuse-derived Fuel from Presently Inappropriate Waste Fractions

(Juan Carlos Hernández Parrodi, 2020)

Master theses, completed by 01st April 2021

- Feuchtebestimmungen von Einsatzstoffen im Stahlwerk (Determination of moisture content in steelworks raw materials) (Nikolaus Voller, 2020)

- Vergleichende Potenzialabschätzung von nass- und trockenmechanisch aufbereiteten gemischten Siedlungsabfällen (Comparative potential assessment of wet- and dry-treated mixed municipal waste) (Dunja Füller, 2019)

- Auswirkungen äußerer Einflussfaktoren auf die nahinfrarot-basierte Erkennung und Detektion von Kunststoffen (Effects of external influencing factors on the near-infrared-based identification and detection of polymers) (Thomas Spanlang, 2018)

Bachelor theses, completed by 01st April 2021

- Überprüfung der Machbarkeit einer sensorgestützten Analyse von Schüttgütern aus PE-Flakes auf Basis von VIS-Technologie zur Qualitätssicherung (Verification of the feasibility for a sensor-based analysis of bulk goods made of PE flakes based on VIS technology for quality assurance), (Laura Lederle, 2020)

- Aufbereitung von Ersatzbrennstoffen zum Einsatz als Ersatzreduktionsmittel im Hochofenprozess (Processing of substitute fuels to be used as substitute reducing agents in the blast furnace process), (Peter Haslauer, 2020)

- Einfluss von Oberflächenrauheit und Wasserbenetzung auf die Erkennung und den Austrag von Kunststoffen mittels sensorgestützter Sortierung im nahinfraroten Bereich (Influence of surface roughness and surface moisture of plastics on sensor-based sorting in the near infrared range),

(Sabine Schlögl, 2018)

Further theses (Secondary technical college thesis, upper-secondary academic school thesis), completed by 01st April 2021

- Ökonomisch ökologischer Vergleich von Primär- und Sekundärrohstoffen,

Aufgabenstellung: Beschreiben des kumulierten Energieaufwandes und der Kunststoffarten Polyethylen, Polypropylen, Polystyrol (Economic and ecologic comparison of primary and secondary raw materials, task: Describe the cumulative energy exoenditure and the types of polymers polyethylene, polypropylene, polystyrene)

(Raphael Wieser, HTL Leoben (Secondary technical college Leoben), Secondary technical college thesis, 2020) - Ökonomisch ökologischer Vergleich von Primär- und Sekundärrohstoffen,

Aufgabenstellung: Beschreiben des Treibhauspotenzials und der Nichteisenmetalle Aluminium und Kupfer (Economic and ecologic comparison of primary and secondary raw materials, task: Describe the global warming potential and the non-ferrous metals aluminium and copper)

(Chiara Ramprecht, HTL Leoben HTL Leoben (Secondary technical college Leoben), Secondary technical college thesis, 2020) - Kunststoffe als Umweltproblem am Beispiel der Stadt Eisenerz (Plastics as environmental problem in the city of Eisenerz),

(Lavinia Zauner, BORG Eisenerz (Upper-secondary academic school Eisenerz), Upper-secondary academic school thesis, 2019, FFG "Talents - Internships for high school students 2019 ")

With the following form you can directly contact the infrastructure responsible Mister Dr. Gerald Koinig.

Gerald Koinig

Dipl.-Ing. Dr.mont.

Scientific staff

Phone: +43 3842 / 402-5143

Cell: +43 670 / 20 64 755

Fax: +43 3842 / 402-5102

E-mail: