Digital Waste Research Lab

At the Chair of Waste Processing Technology and Waste Management (AVAW) at the Montanuniversitaet Leoben, a research facility for the characterisation and sorting of bulk materials was put into operation in St. Michael in Upper Styria under the name "Digital Waste Research Lab" (2023). The current focus (2024/2025) is on digital waste analysis, process engineering machine optimisation, digital networking, and data-based dynamic control for large-scale experimental research, which are essential sub-areas in developing a recycling-oriented Smart Waste Factory.

Application and Hardware

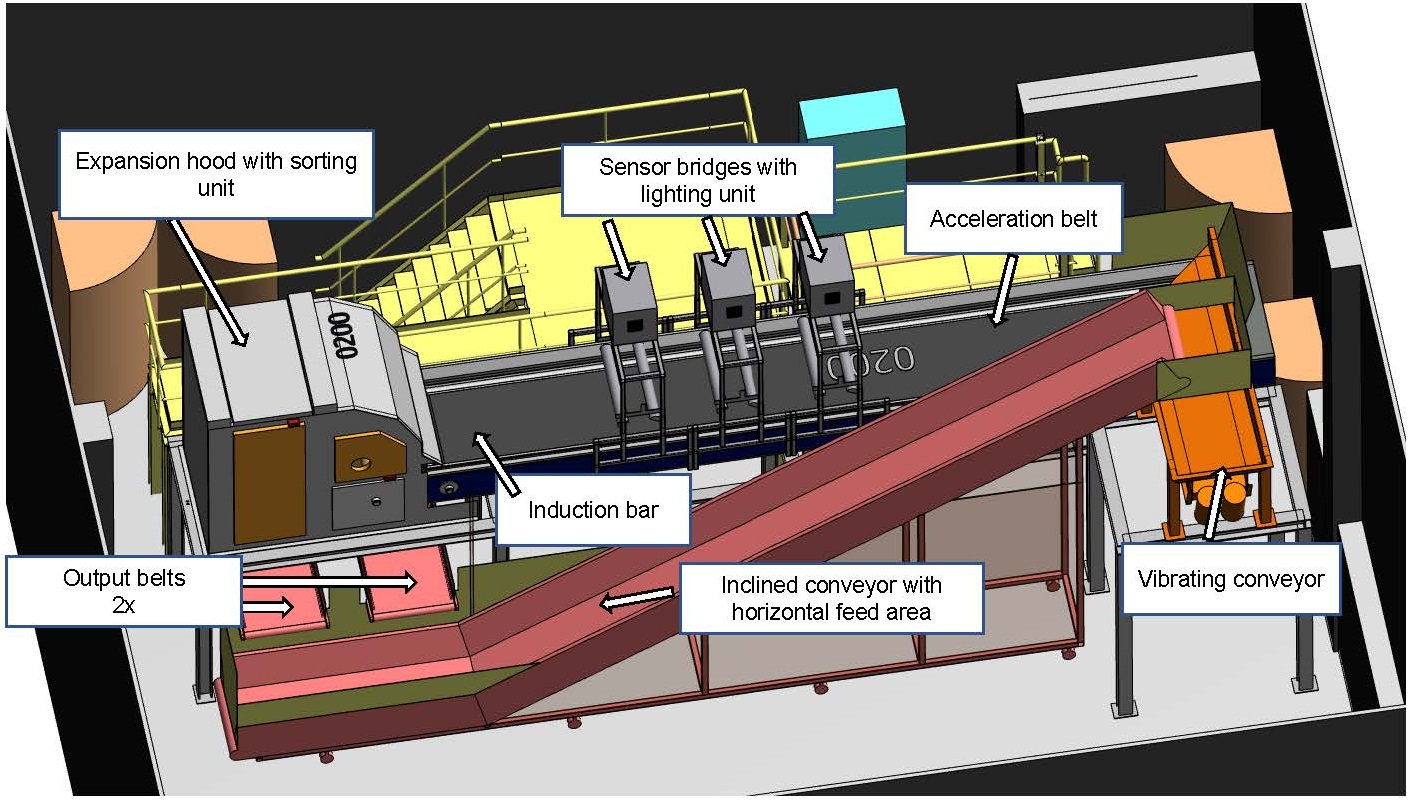

The facility is designed to treat non-hazardous waste with a particle size range of 30-300 mm. The speed of the entire system is individually adjustable. An inclined belt is used to transport the material to the vibrating conveyor and can be used flexibly due to its installation on wheels. The systems output belts are mounted on a rail system and can be moved in position according to the operating mode (see below). The inclined conveyor can feed the material in various ways into the plant: discontinuously, using buckets, tubs, big bags or directly from containers, or continuously, using upstream units. The material is then distributed using a vibrating conveyor and a high-speed accelerating belt (working width 1 m, speed up to 3.5 m/s). On the acceleration belt, characterisation is carried out by individual sensors with the possibility of sorting by using a pneumatic nozzle comb (80 nozzles).

Sensors

The plant is equipped with semi-mobile measuring bridges above the acceleration belt. These can accommodate a variety of sensors and measurement devices for on-time and online analysis of bulk waste materials and specific waste objects/articles. A near-infrared (NIR) camera records NIR spectra with a resolution of 9 nm at up to 446 Hz in the wavelength range of 900-1,700 nm at 320 spatial pixels, with a dimmable infrared halogen lighting unit serving as the emitter. A 4096 * 2-pixel line scan camera with two dimmable LED strips is used for RGB data. A 3D laser triangulation system is used to determine volume information. A 25 mm grid induction bar installed under the acceleration belt is used for metal detection. In addition, hardware for six measurement positions is available for Radio Frequency Identification (RFID) measurement technology, which can be installed anywhere in the system.

Software

The data obtained from the sensors is processed with different software solutions depending on the application. The available software package is used to make sorting decisions based on the information from the NIR and RBG sensors and the induction bar and to control the individual nozzles to eject the particles at the right time. All sensor data is recorded for further processing via a "data and analysis platform". Depending on the sensor, different statistics and parameters can be recorded, summarised, graphically displayed, or exported for further processing.

Operating Modes

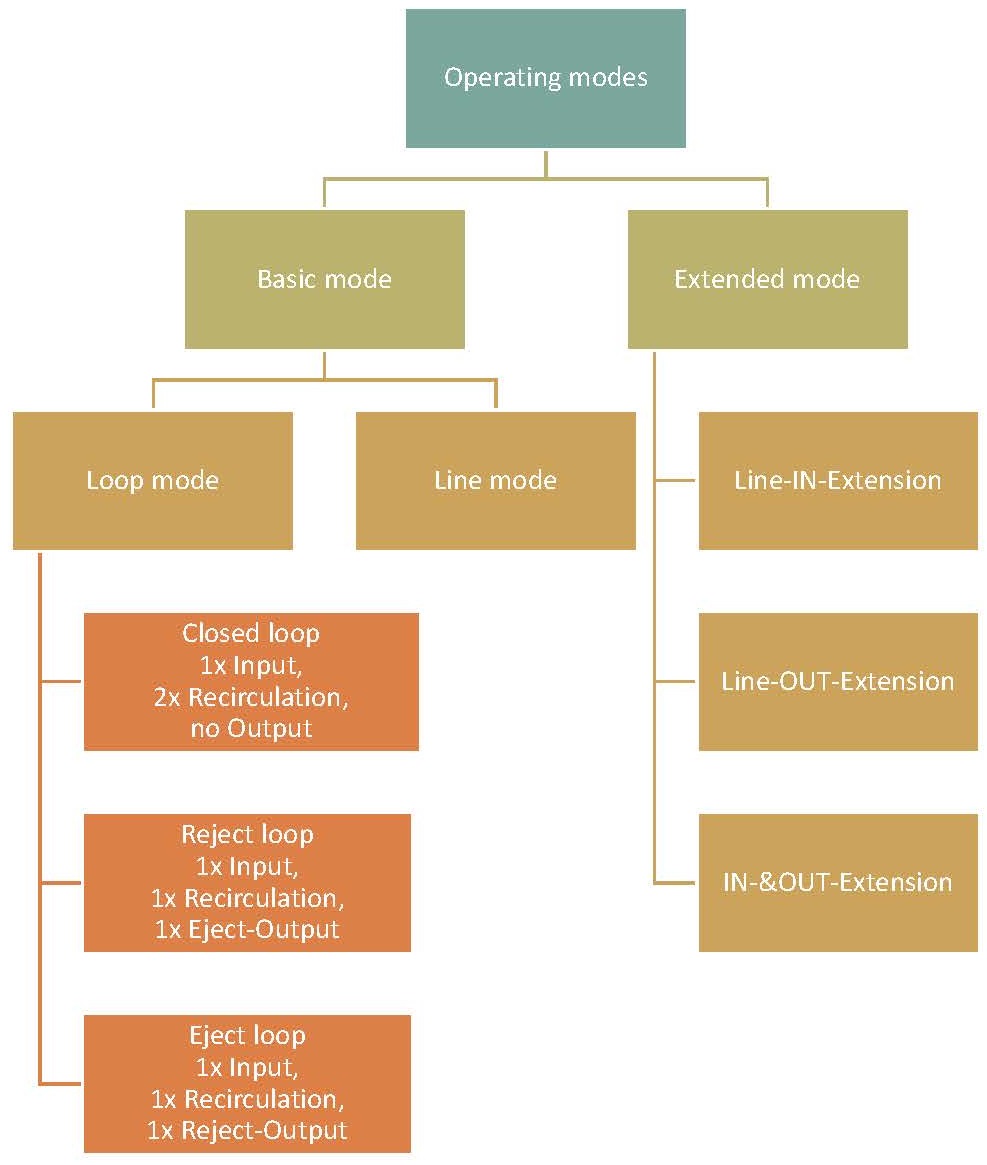

Due to the flexible and partially mobile design of individual components, the research facility offers a wide range of applications, which can be divided into two modes of operation:

Basic mode

Depending on whether the material to be analysed passes through the system only once or (at least partially) several times, a further distinction is made here between line mode (no material recirculation) and loop mode (recirculation of at least one partial flow).

Extended mode

The outdoor asphalt area in front of the plant allows the existing infrastructure to be adapted with both upstream (line-IN-extension) and downstream (line-OUT-extension) units or a combination of both (IN-& OUT-extension). This allows the system to be individually customised with shredders, screens, air separators, metal separators (ferrous, non-ferrous), ballistic separators, conveyors, etc.

Applications

Digital waste analysis on-site

Among other things, the plant is currently laying the groundwork and developing representative methods in the field of digital waste analysis. Based on sensor data and machine settings, a defined process for determining various quality criteria of a material stream is being developed to complement and partially replace specific manual analyses (screening, sorting) and laboratory analyses for determining chemical parameters in the future.

Use of sensors as mobile units in real processing plants

Based on an already successfully tested "waste scanner", the existing sensor technology of the test plant can be used individually as a mobile unit in real plants. The sensors provide data during actual plant operation and, thanks to the relatively simple installation of the system in the plant, can also record long-term data, be used to create modelling data for machines, or be used to evaluate process behaviour (monitoring).

See the following article for more details (click).

Location

Murfeld 3, 8770 St. Michael in der Obersteiermark, Styria, Austria

With the following form you can directly contact the infrastructure responsible Mister Dr. Renato Sarc.

Renato Sarc

Ass.Prof. Dipl.-Ing. Dr.mont.

Working Group Leader

Phone: +43 3842 / 402-5105

Cell: +43 676 / 84 53 86-805

Fax: +43 3842 / 402-5102

E-mail: